Corporate Social Responsibility 2022

We recognise sustainability to be that which “considers the economic, social and environmental needs for us and others at the present time and the needs of future generations”. This means we believe it is crucial for businesses to behave fairly and ethically towards society, customers, suppliers, environment, and employees. At the Traffic Group Ltd we are committed to a CSR policy that enables sustainable development. We treat all our stakeholders, including the environment, fairly and ethically. This has always been central to our product design and throughout our business activities.

We are committed to supporting the internationally-recognised ‘Sustainable Development Goals’, and we take a holistic approach to being a good neighbour in local, national and international communities. We hope to be pioneering in our corporate social responsibility within our sector and seek to encourage and collaborate with our industry partners to magnify our collective efforts.

THE BIGGER PICTURE

WASTE & WATER

DECARBONISATION

COMMUNITY RESPONSIBILITY

SKILL DEVELOPMENT & KNOWLEDGE SHARING

CIRCULAR ECONOMY

SUSTAINABLE VALUE CHAINS

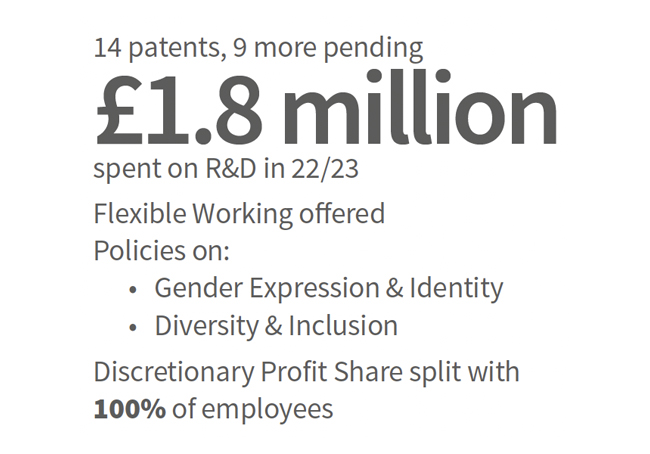

GOOD BUSINESS PRACTICE

Our sole purpose as a family business is to offer safer, greener, more efficient highways products and operations.

A dedicated team of 130 employees helps drive a culture of continuous improvement across all aspects of our business and ensures that treatment of all our stakeholders, including the environment, is fair and ethical.

Previously, our contributions across the three areas of sustainability (the environment, the economy and human society) have only been demonstrated in our product design and our everyday business activities.

We have now reached a size that means we have the available resources to start effectively reporting our Corporate Social Responsibility (CSR) activities. This will allow us to benchmark our Group’s efforts against previous years and hold ourselves accountable to commitments and continuous progress towards holistic sustainable development.

A Word From Our Group MD

“Our investment and activity across the Group is showing real improvements and our latest report for 2022 shows some significant gains.

Whilst a significant amount of resource is being invested on some of the bigger initiatives, it is often the smaller items which can yield surprisingly big improvements. At one of our recent Company Communications days we discussed ‘sweating the small stuff’. This is everyday things that all of us can do just turning the lights off/ down, turning the heating down, washing hands in cold water or just taking one less paper towel each time you wash your hands. As an example, a single recycled paper towel is 20g CO2e, so taking one less three times a day on average can save 10Kg per person per year. Continuing this theme, we are rolling out a pilot of switching to bamboo based toilet paper. If successful this should give us gains over our existing recycled paper product.

Lastly, there now appears to be sustainability discussion emerging in the business which I am lead to believe is quite normal after the relatively easy gains have been made. That is, the conflict between sustainability as a general item and the CO2e emissions made to make the gains. In the next period we are going to have to look for a more sophisticated framework to help make the best choices possible.

Hopefully, you are as pleased as we all are in the progress made and I would like to thank all those who have really rolled up their sleeves to make great progress.”

Peter Hutchinson – Managing Director, The Traffic Group

A word from our Group MDs

As MD of a Traffic Group company it may sound shocking to say how little our formal CSR and Sustainability activities have affected us. The reason being that the ethical heart of the Traffic Group companies had embraced the essential traits of Sustainability many years before it became a business buzz.

The first issue of our annual Sustainability Report was testament to the fact that Traffic Group has lived a philosophy of “doing the right thing” well before it was documented and evidenced. In the same way that Quality cannot be inspected in as an afterthought, any business paying lip-service to Sustainability soon shows its true not-so-green colours. The fact the Traffic Group companies had already put an array of measures to meet Sustainable Development Goals in place, often without consciously realising it, underlines the culture that lives within.

We are a set of businesses that manufacture and consume materials but, in doing so, we have always understood that the products we produce must have longevity in the market, be upgraded to match changing needs and supported throughout a long and useful life. That demands careful design, forethought and vision. We believe that our products have a positive impact on society and that the way in which we work with our partners also gives them the opportunity to add real further value. Nothing we produce can be classed as quick-tech, disposable or gadgetry – we actually provide the products that make journeys and communities demonstrably safer, greener and more efficient and we are proud of that.

These foundations have underpinned the formulation of more formalised programmes of ongoing work that this second annual report highlights. Perhaps, what it shows best, is that we have a commitment at the heart of what we do to make our businesses successful not at any cost but with true care and attention to our global impact.

Steve Walker – Managing Director, MAV Systems

Sustainable Development Goals

The UN Global Compact has outlined detailed indicators in the form of Sustainable Development Goals (SDGs) to help structure responsible business efforts.

Although we inherently contribute to a wide range of SDGs, we have chosen to consciously focus our efforts on eight. These are evenly spread across Biosphere, Society and Economy Goals to ensure diversity within our CSR strategy. The table below explains in more detail the logic behind our choices.

Zero Hunger

End hunger, achieve food security and improved nutrition and promote sustainable agriculture.

Good Health & Well-Being

Ensure healthy lives and promote well-being for all at all ages.

Quality Education

Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all.

Industry, Innovation and Infrastructure

Build resilient infrastructure, promote inclusive and sustainable industrialisation and foster innovation.

Responsible Consumption and Production

Ensure sustainable consumption and production patterns.

Climate Action

Take urgent action to combat climate change and its impacts.

Life of Land

Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, halt and reverse land degradation and halt biodiversity loss.

Good Health & Well-Being

Strengthen the means of implementation and revitalise the global partnership for sustainable development.

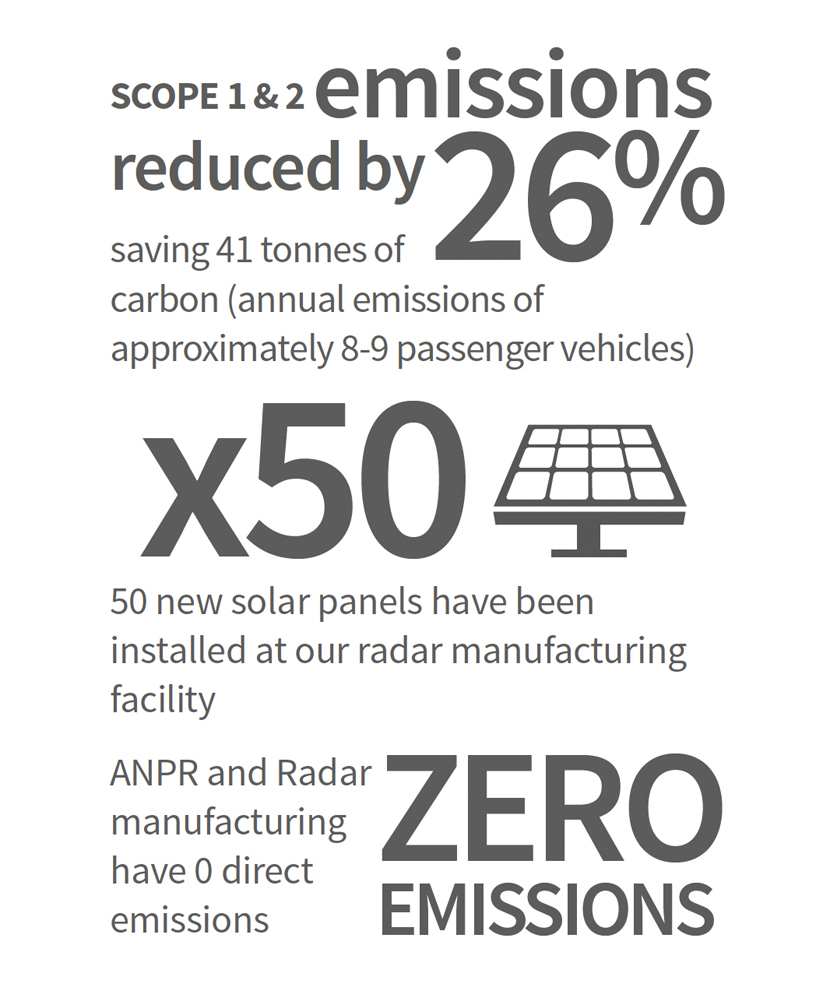

Decarbonisation

We will be using the Green House Gas Protocol’s methodology for GHG accounting to communicate our decarbonisation efforts.

Emission figures will use the unit CO2e to encompass equivalent GHGs, and calculated using the UK Government Conversion FactorsÅ.

SCOPE ONE

SCOPE TWO

Additional Reporting Figures

Renewable Energy Generation

Emissions Breakdown by Depot

AGD

MAV

TGS - Pike Works

TGS - Hollco

Company Vehicles

TGS Other SItes

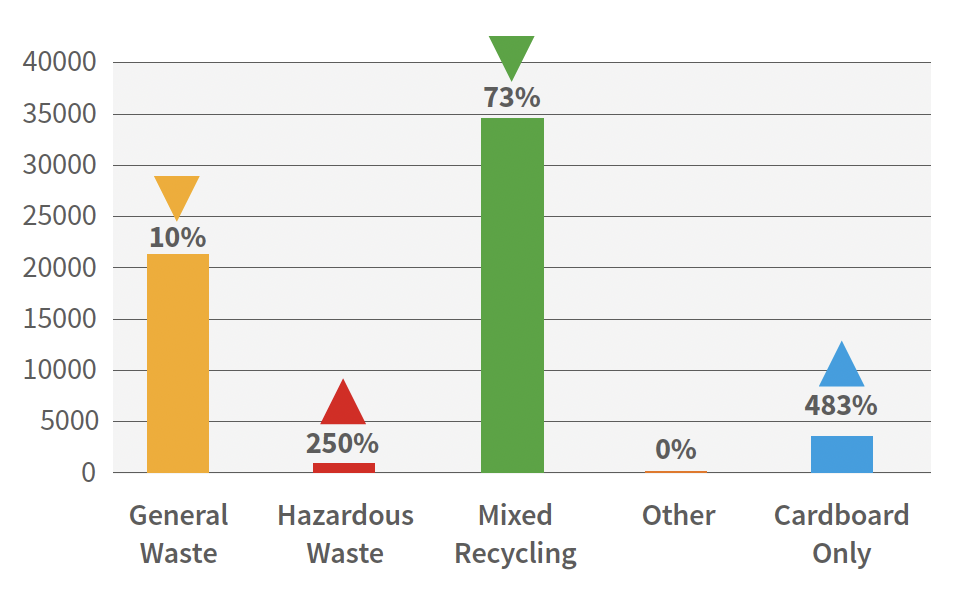

Waste & Water

Reducing waste was a clear top priority when we asked our team for feedback on our CSR efforts. As a result, significant effort has been put in to reducing waste, saving well in excess of a tonne of waste per month on average.

- MAV introduced plastic recycling to their remote location, previously thought unattainable, becoming zerowaste-to-landfill.

- AGD introduced polystyrene recycling, becoming zero-waste-to-landfill.

- TGS introduced mixed recycling at Pike Works and flexible plastic recycling across manufacturing sites, becoming zero-waste-to-landfill.

Current Waste Streams

TTG 2022 Annual Average Waste by Type (KG)

TTG Annual Average Waste to Landfill (KG)

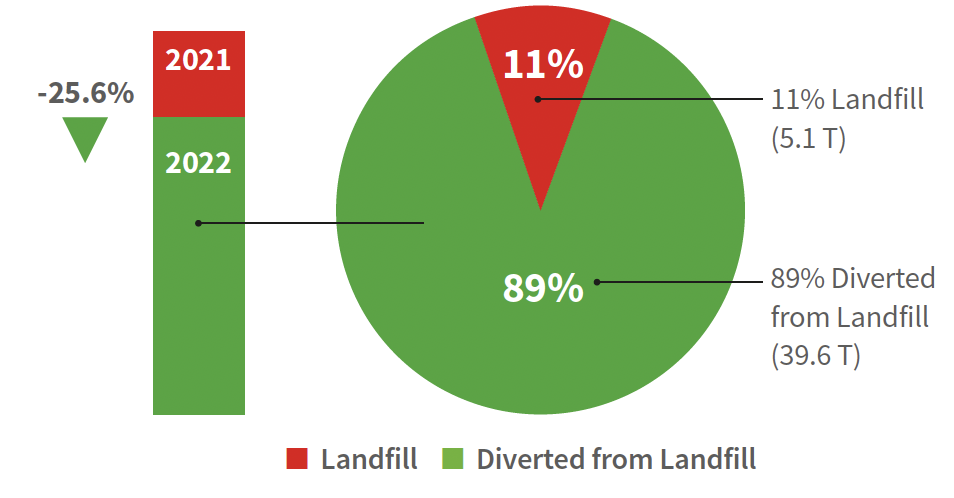

We are now Zero-Waste-to-Landfill

At the beginning of the period, we minimised waste to landfill to only 5.1 tonnes. Since then, our initiatives are now such at the end of the period, we had achieved Zero-Waste-to-Landfill.

All our general waste is now to energy-from-waste schemes. Our next step is to externally confirm the achievement of zero-waste-to-landfill across all The Traffic Group sites, and continue to reduce waste where we can.

Water

Our water use mainly comes from general facilities, kitchen use, and cleaning company property. Some of our locations are not fitted with water meters, which we are hoping to install in the coming months to enable full reporting. Although we continue to report on our consumption figures, we aimed to focus on waste reduction this year and will shift our attention to the measurement of water consumption soon.

AGD

MAV

TGS - Pike Works

TGS - Hollco

TGS Other Sites

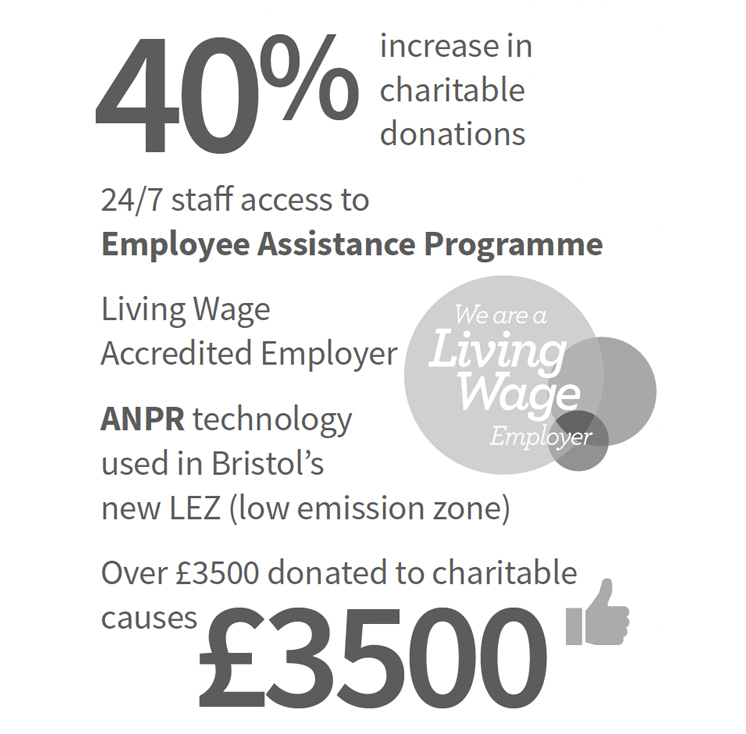

Case Study: Bristol Low Emission Zone

We are thrilled to share the news that MAV’s ANPR technology is being used in Bristol’s Low Emission Zone since summer 2022, which is bringing significant environmental and social benefits to the local community. By monitoring vehicle emissions and enforcing compliance, our ANPR cameras are playing a critical role in reducing air pollution and promoting a healthier environment for the community of Bristol.

Ukraine Support

Our Community Responsibility includes being a good neighbour within the international community. In response to the ongoing events in Ukraine and its bordering countries, we have:

- Donated í300.96 to ‘Baby Lifeline Ukraine Appeal’ – 50% TGS employees through cake sales, which TGS matched.

- Donated í350 to Association of Ukrainians in GB (AUGB) Emergency Appeal.

- Shared advice in our internal Newsletter to empower employees.

Radix Partner

It is with deep sadness that we announce the passing of Radix founder Dick Duley in 2022. In his memory, The Traffic Group has donated í1,000 to Prostate Cancer UK. The contributions of Dick Duley and Milan Fuchs to the traffic industry, particularly in making roads safer for vulnerable pedestrians through the development of the ‘rotating cone’ tactile equipment, have been immeasurable. As part of AGD’s portfolio, Radix continues to be synonymous with this essential technology.

Care First Partnership

In 2022 we adopted an Employee Assistance Programme (EAP) providing 24/7 access from Care First’ to support our employees and their close ones with their mental health and well-being. This decision was catalysed by the prolonged impacts of COVID and the increasing financial pressures faced by individuals.

Warning: Trying to access array offset on value of type bool in /home/sustainabilitytr/public_html/wp-content/plugins/penn-toolkit/templates/modules/blocks/image.php on line 4

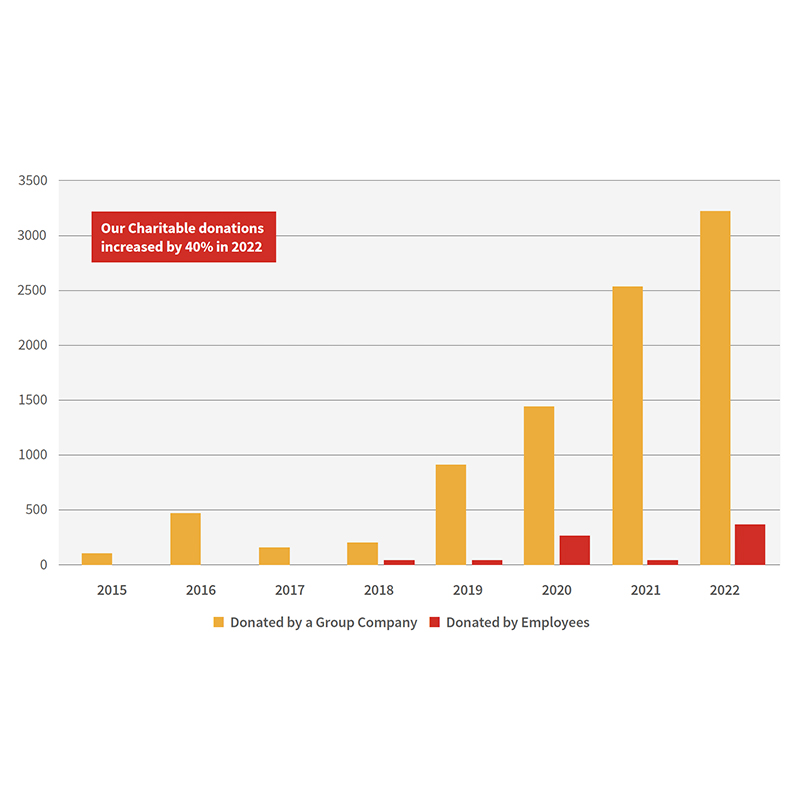

Monetary Charitable Donations Recorded per Year (£)

Donations in 2022 include:

Mind, Sue Ryder, Air Ambulance, Action for Children, Prostate Cancer UK, Cottage Community, Matthew’s friends, and Birmingham Hospice Charity Partnership.

Employee-Led Action

One of our employees completed a November Push Up Challenge for Cancer Research. They managed 3300 push-ups and raised í205!

One of our employees volunteered along with 300-400 people to pack two full lorries with donations for Ukraine at Gloucester organised event.

Skill Development & Knowledge Sharing

In the past, members of the senior management team have participated in events at local educational institutions such as Cirencester College, University of Gloucestershire, Warwick University, and have made Radio show appearances – most recently joining John Darvell on BBC Sounds. Our senior management team also includes a STEM ambassador.

Work experience is offered to Year 10+ students from local schools giving them the opportunity to work across different areas of the business, including Production, R&D, Customer Services, to get an overview of working life and how a business operates.

Apprenticeships have been offered to employees of all ages, where it is felt there is either a skills gap or to assist them in progressing within the business. Recently, two employees have completed their L3 Advanced Apprenticeships in Electrical & Electronic Engineering, which has resulted in one of them transferring from Production into Engineering as a PCB Design Engineer.

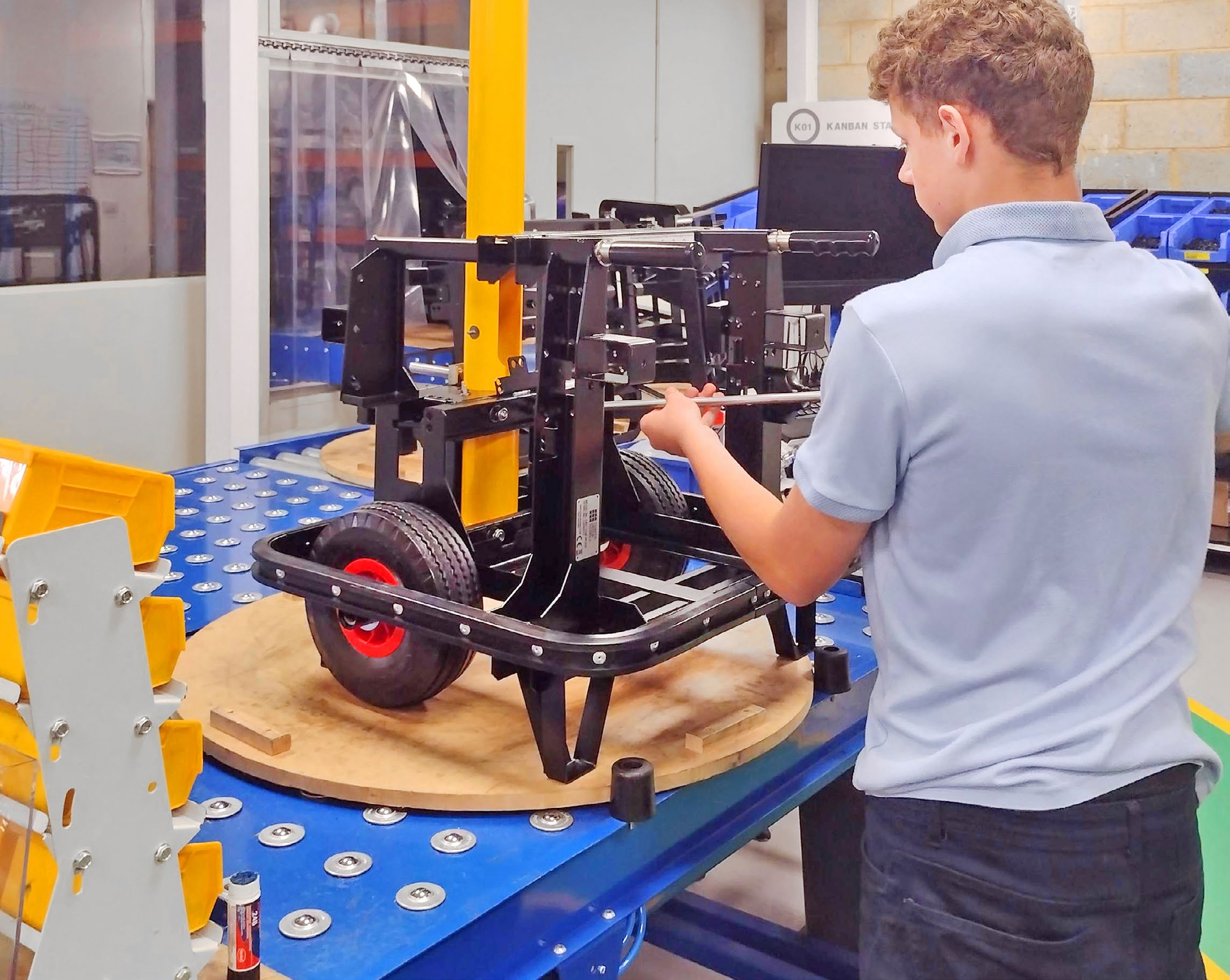

Work experience

The Traffic Group offers work experience to Year 10+ students. Typically, these students will be given an overview of the business including production, engineering and commercial. In 2022, TGS has had two work experience students:

TGS Hollco Y10 WE Student (Todd – right) – Todd assisted in trialling additional training courses such as conflict management in addition to the overview of our operations, providing a wide-ranging introduction to topics within the workplace.

“My work experience has been very valuable and useful for me, and I am very appreciative of the time that you and your colleagues took out to help me. I enjoyed helping to assemble the traffic lights most and seeing how Sarah’s job works with the balance sheets. I think that this experience will help me in the future because it has given me a valuable insight into a business and has made me possibly want to start my own business one day” – Todd

TGS Pike Y10 WE Student (Kamil) – Kamill expressed an interest in computer programming and technology and developed a miniature 4-way set of traffic lights running on fixed times in addition to the standard work experience.

“It was great to participate in the work experience, helping young minds realise their potential in school and the future workplace. I think Kamil left excited to embark on new programming adventures armed with some resistors, LEDs and an Arduino.” – Tom, TGS Test Engineer

Apprenticeships

Tom Robertson (main image)

Tom began working for Hollco as a production operative back in 2015 and expressed a keen interest to evolve his role when new opportunities became available in product development for the RC2. After demonstrating exceptional progress in his new role within the software engineering project team, Tom was encouraged to pursue his BTEC L3 qualification. As TGS’ sole Test Engineer, Tom now plays a crucial part in testing all software used in new and existing radio-connected portable signals at TGS to ensure highquality functionality. This is done alongside completing NVQ design projects for our testing facility.

Qualifications: BTEC Level 3 Electrical/Electronic Engineering

Mateusz Batugowski (inset image)

Mateusz has worked at AGD for 6 years, initially recruited as a production operative. His positive attitude, engaging personality and willingness to take on a challenge is demonstrated through his progression from moving into the service centre and enrolling in a BTEC Electronic course early on, to undergoing intensive training and joining the engineering team prior to the retirement of his colleague and mentor. He has made exceptional progress and is now responsible for designing all PCBs for the products being developed by AGD and works closely with the electronic design engineers.

Qualifications: BTEC Level 3 Electrical/Electronic Engineering, HNC in Electrical/Electronic Engineering, currently studying HND from September 2022-2024.

Sustainable Value Chains

As a group, we continue to adhere to our Conflict minerals and Modern-Day Slavery Policies, which can be found at: https://sustainability.traffic.group/company-policies/

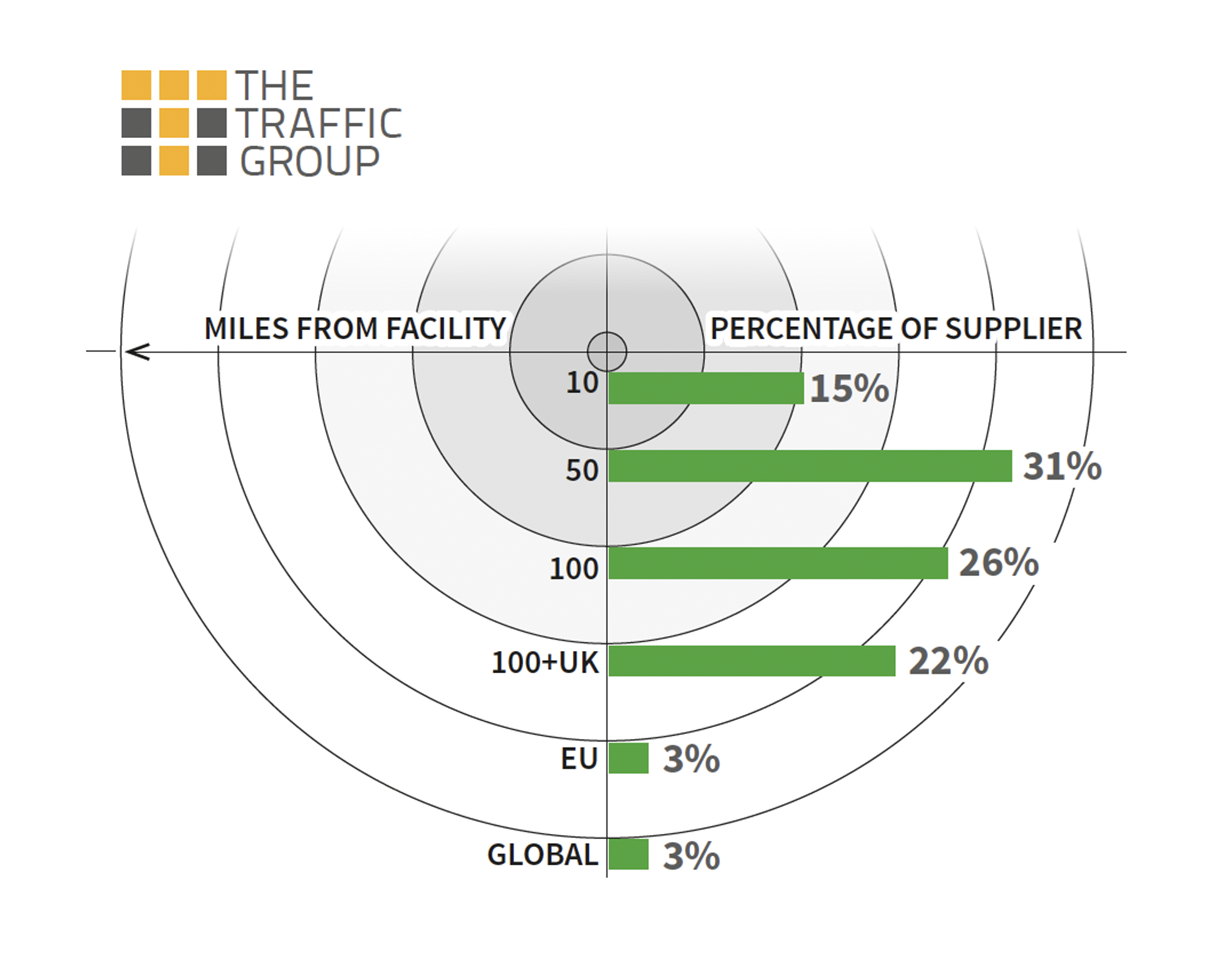

100% of all products at The Traffic Group are designed and made in the UK

95% of all TTG suppliers are UK-Based

The locality of each company’s suppliers according to percentage of suppliers in each category of straight-line distance from the relevant facility.

With many suppliers holding long-term agreements, our relationships have matured with us and our partners over the years. This has helped us advise local businesses based on our experiences, share ideas and knowledge to advantage us both, as well as just making the day-to-day more enjoyable.

Case Study - Stantek Electronics Ltd & AGD Systems

One of our longest standing relationships in The Traffic Group is that between AGD Systems and Stantek. Stantek supply some of the printed circuit board assemblies (PCBAs) as well as cable assemblies and are only 7 ó miles down the road from AGD.

Stantek has embraced sustainability in their business and have initiatives which range from introducing 4-day working weeks, to only purchasing second-hand furniture for their offices.

“Stantek’s growth from a small free-issue company to a multimillion-pound turnover subcontractor may never have been possible without the support and guidance of AGD. Since the start of our relationship in 1992 AGD’s guidance and support has been a vital part of Stantek’s success. Throughout our 30-year relationship, AGD’s support and advice has never wavered and the relationship today continues to be as strong as it was as the very start.” – Errol, Director at Stantek

AGD’s entire product range benefits from high standard, specifically-designed cables and brilliant twoway communication with Stantek helping us problem solve at multiple levels.

Stantek have grown from a 1,000 Square Feet facility in 1993 to their now current premise since 2012 12,000 Square Feet.

Decarbonisation

- Scope 1 emissions

- Scope 2 emissions

- Scope 3 emissions

- Renewable energy generation on-site

- Scope 1 & 2 emissions per square foot by depot

- EV charging points

- CO2 per vehicle

- Statistics on Company Vehicle Electrification (if hybrid vehicles are 0.5 electric)

Waste & Water

- Average total mass of annual waste

- Average mass of waste to landfill

- Average mass of waste diverted from landfill (breakdown by waste stream/depot on page 11)

- Average mass of waste generated per í1000 turnover (breakdown by depot on page 11)

- Average annual water consumption per employee (breakdown by depot on page 11)

- Percentage of recycled materials in products (only case study available)

- Number of products repaired and refurbished

- Percentage of Products with end-of-life care diagrams*

Community Responsibility

- Charity Partnerships & Case Studies

- Annual monetary charitable donations

- Hours spent volunteering by employees in company time

Skill Development & Knowledge Sharing

- Number of employees participating at knowledge sharing events.

- Employee attendance for internally held events and training days.

- Work Experience placements.

Sustainable Value Chains

- Contact with key suppliers in relation to: Conflict Minerals, Modern Day Slavery, Rare Earth Elements

- Employee attendance for internally held training sessions for value chain sustainability

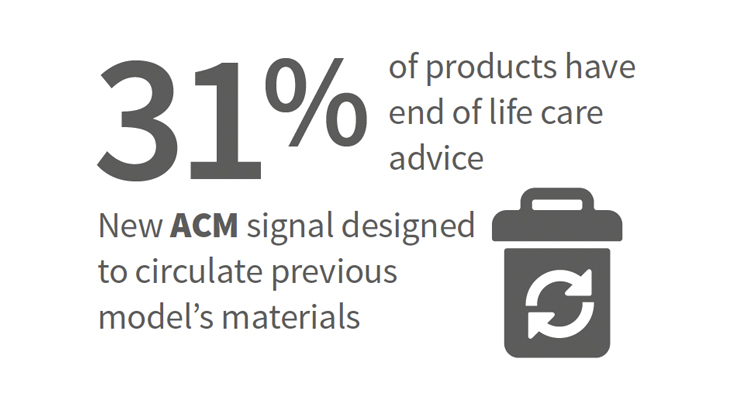

Services to Extend Product Life

Driving forward with its strategy to support the UK’s sustainability goals, TGS has launched its eco-conscious Evo ACM series of portable traffic signals. The metalwork and electronics of the company’s established Evo Multi product line have been recycled and remanufactured to create a new, modern and environmentally responsible signal.

In the development of TGS’s new Evo ACM Signals, we’ve kept in mind the materials used in the previous models. The new ACM Signal can be almost entirely repurposed from the old models – even the newly designed plastic signal head.

Extending life of product materials

We try to equip our customers with the knowledge to sustainably dismantle our products when they’re no longer useful using ‘End-of-Life’ (EOL) diagrams. Of our entire product range, we’ve determined the percentage of products with end-oflife care information. We’ve reclassified this metric to only include full product diagrams, which has shown a decrease in percentage this year.

Circular Economy Statement

End of Service EVO Signals

TGS Pike Works’ portable Evo Series

signals are returned to our depot in Aston, Birmingham.

Heads are Dismantled

The team dismantles the old signal into the individual materials in preparation for material reuse and recycling.

Plastic is Powdered Down

The plastic signal head is returned to our rotational plastic moulding supplier to be powdered down for re-use.

Rotational Tooling

This powder is used in the rotational moulding machines in specialist tooling developed by the design team at TGS in collaboration with our partner.

New Heads

The 100% recycled plastic heads produced are returned to TGS.

EVO ACM is Assembled

The brand-new Evo ACM signal is then assembled at the Pike Works manufacturing depot.